Strategic identification of strains with the highest potential for each product and feedstock combination, using our proprietary strain collection and beyond

Development of cutting-edge genetic tools capable to domesticate microorganisms rapidly and precisely

Initial Techno Economic Assessment (TEA) to determine whether the project is industrially and economically viable with an acceptable ROI

Designing process and nutrient media to maximize product yield, minimizing costs and increase scale up success

Process monitoring and control of key parameters by implementing real-time sensors and a strong analytical platform

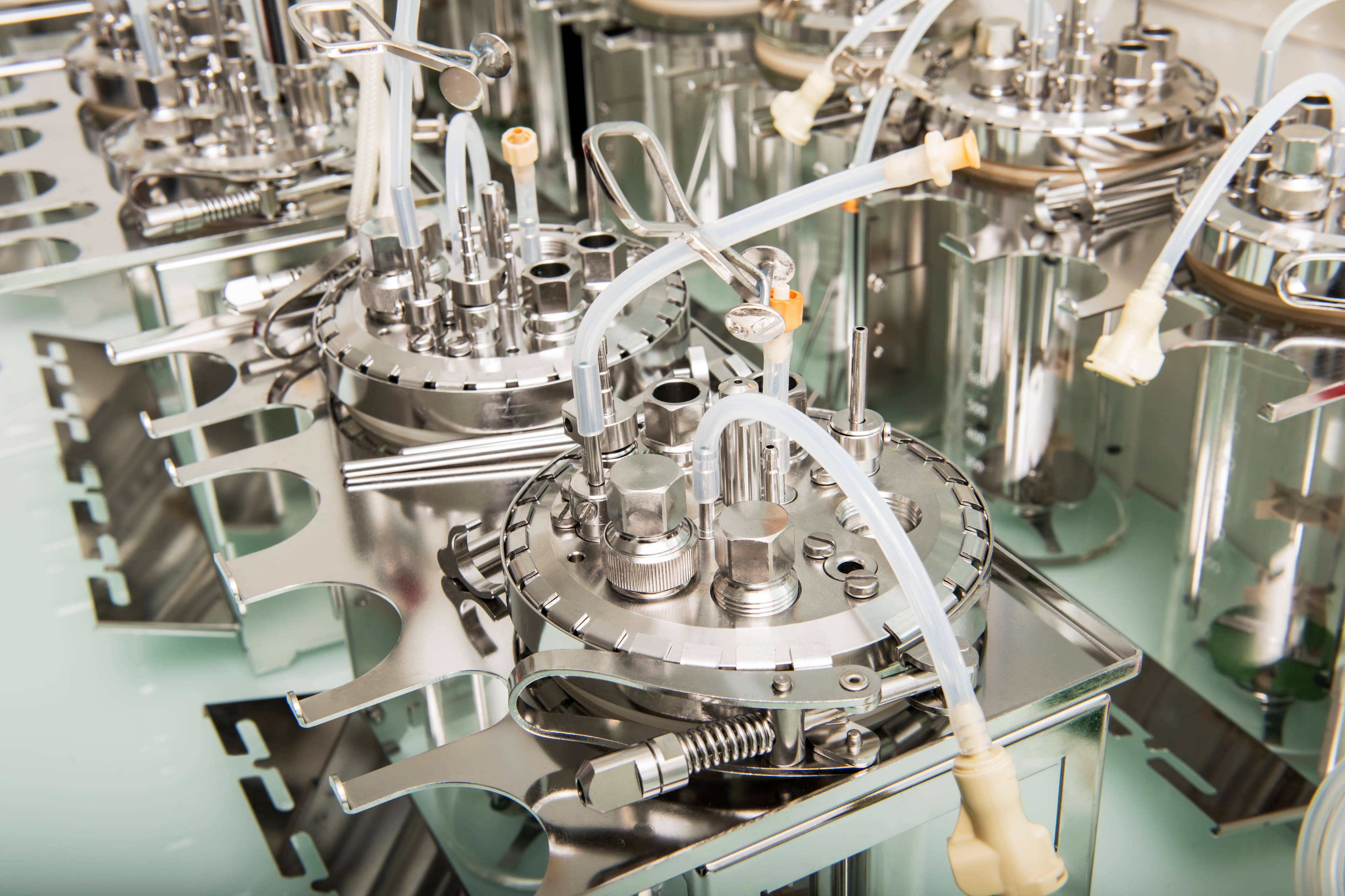

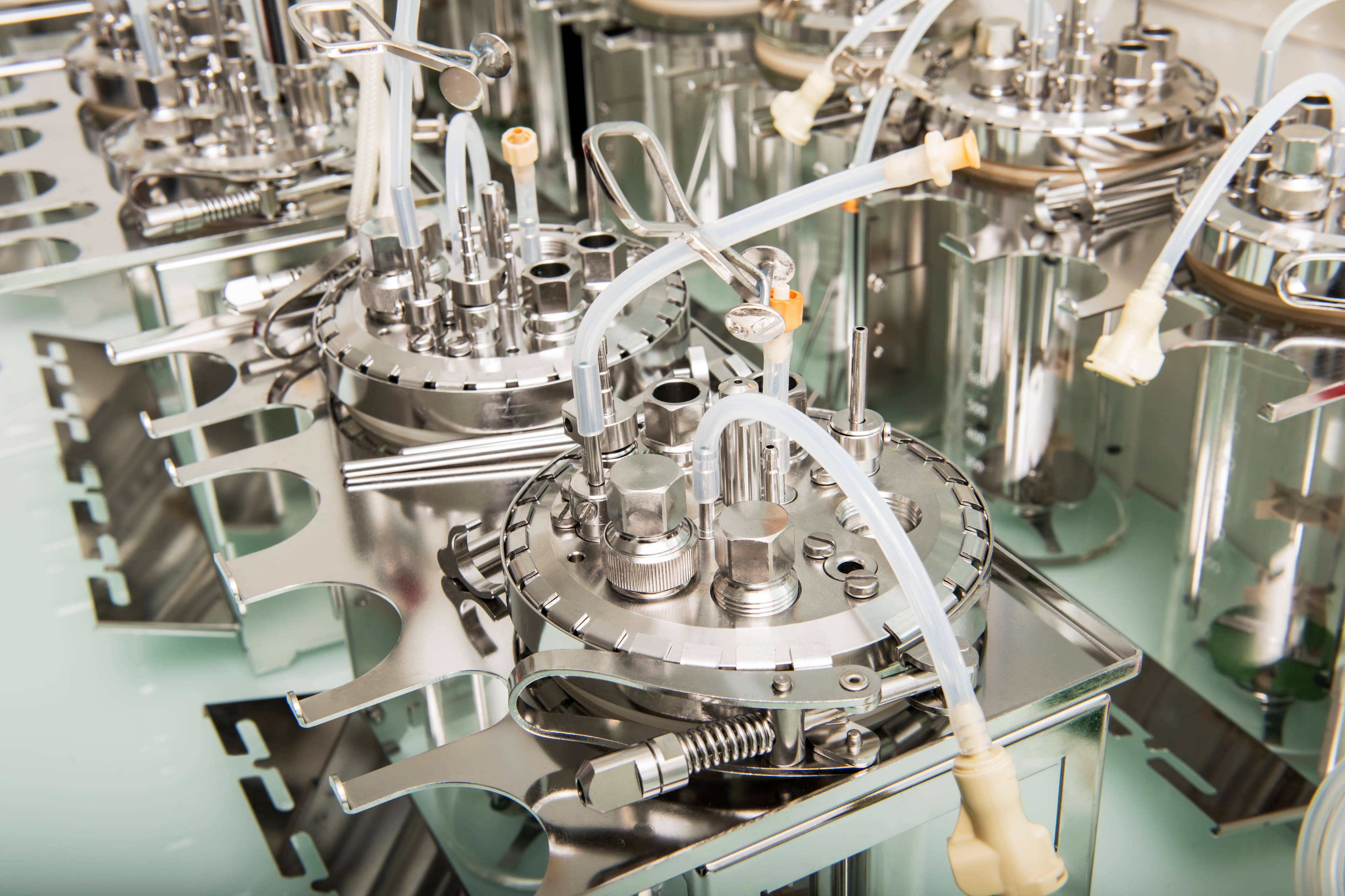

Down-scale process setup of industrial condition to optimize fermentation parameters to ensure process robustness and scalability

Optimization of central metabolism using -omics-guided strategies, flux balancing, fine-tuning of gene expression, and more

In-silico enzyme research, design and optimization followed by in-vivo validation: rapid iterative cycle of enzyme improvements

Robotic platform to foster strain & enzyme screening, gene cloning, sample preparation and a specific 48 wells fermentation robot

Fermentation optimization from the lab, up to the 20L. It’s the right scale before starting the industrial transfer (USP)

Abolis works with trusted partners to develop and manufacture your product from pilot to industrial scale

One-stop boutique supporting from concept development to commercial manufacturing, integrating project strategy, technical execution, and manufacturing support via selected partners

Strategic identification of strains with the highest potential for each product and feedstock combination, using our proprietary strain collection and beyond

Development of cutting-edge genetic tools capable to domesticate microorganisms rapidly and precisely

Initial Techno Economic Assessment (TEA) to determine whether the project is industrially and economically viable with an acceptable ROI